DER Monetization for Government facilities

Case Study: Lake Gaston Water Supply Pipeline

Virginia Beach, VA – Faced with the prospect of losing hundreds of thousands of dollars in demand response revenue, this Virginia Beach site discovered a way to keep the money flowing without interruption.

THE CUSTOMER: LAKE GASTON WATER SUPPLY PIPELINE

The Lake Gaston Water Supply Pipeline, also known simply as Lake Gaston, is at the heart of the economic vitality of the City of Virginia Beach (see our City of Virginia Beach case study). Located west of the city, on the North Carolina border, Lake Gaston employs six vertical-turbine centrifugal pumps, each with a nominal capacity of 10 million gallons per day, to supply Virginia Beach with the 30 million-plus gallons of treated drinking water that its residents consume each day. (The high-capacity pumps give the station the flexibility to increase pumping up to 60 million gallons per day.) The water flows through a 76-mile-long pipeline (which includes six overhead river crossings) from the lake to facilities in nearby Norfolk for treatment.

Since 2010, Lake Gaston has participated in the demand response program offered by CPower through Virginia’s Department of Mines, Minerals and Energy (DMME). This program pays government entities market rates for curtailing their electricity usage during times of high demand on the grid. Participants save on their energy costs and earn revenue that can be reinvested in upgrades, energy efficiency projects, and more. Lake Gaston’s participation has earned them nearly half a million dollars since 2011 (see chart below).

Steven Poe, the city’s Water Master Planner, assumed management of Lake Gaston in 2015. At the time, Lake Gaston had already earned more than $221,000 in DR participation, and Steve understood he could count on a continuing and beneficial revenue stream. Unfortunately, he hadn’t counted on a court ruling that dramatically changed the role of emergency generation in demand response.

THE CHALLENGE: CONFRONTING THE VACATUR

In 2013, the federal Environmental Protection Agency (EPA) issued emission standard exemptions that permitted emergency generators to operate up to 100 hours a year for “emergency demand response.” Lawsuits from environmental groups, state governments, and commercial power generation groups challenged the EPA’s ruling, saying it would hurt air quality and grid reliability. In May, 2015, the United States Court of Appeals for the DC Circuit vacated the 100-hour rule (on procedural grounds). This vacating ruling, dubbed “the Vacatur,” would take effect on May 1, 2016.

The Vacatur threatened to have a disastrous impact on Lake Gaston’s DR participation—and earned revenue. Lake Gaston was designed to pump continuously and could not do so without the use of its diesel engine generator.

The Vacatur left Steve no choice but to withdraw his diesel-powered generator from the DR program. Without it, he not only faced loss of revenue from its participation, but potentially the loss of all DR revenue. If the generator could not be used to sustain pumping during curtailment, then Lake Gaston would not be able to curtail the required power during a called event without jeopardizing Virginia Beach’s water supply. The pumps, then, would also have to be pulled from the program, essentially shutting down the lucrative revenue stream.

Or would they?

Steve felt that the financial benefits of DR participation warranted a closer look for a creative solution. “When we realized we couldn’t curtail anymore with our generator, we didn’t want to miss out on the incentives,” he says.

But to reach their target, they would have to conduct a full shutdown. Could they shut the pumps down—and bring them back up—without damaging both pumps and pipelines? And if they could, would that be enough to continue in DR without damaging their savings and earnings?

THE STRATEGY: SHUT ‘EM DOWN

Full shutdowns are rare in nearly all industrial settings, but Lake Gaston had a precedent. In 2014, a 39-ton coal ash spill on one of the lake’s tributaries forced the pump station to shut down for about two months. This was the first extended shutdown of the pump station in its history and caused a great deal of concern. Lake Gaston was designed to maintain a minimum sustainable pumping rate of eight million gallons per day flowing through the pipeline to maintain water quality and prevent issues with start-up. When pumping resumed, Virginia Beach learned that the pipeline was resilient and could recover with minimal effort.

Using that experience, Steve and his team are able to shutdown the major energy consuming equipment at the pump station – including the pumps and industrial HVAC system – within one and a half hours of being notified of a DR event. They’ve learned that participation without their generator is worth the extra effort of executing full shutdown and start up procedures, which requires monitoring the SCADA system and gradual reduction and startup of pumps to prevent water hammer.

THE CPOWERED SOLUTION: DMME + CPOWER DEMAND RESPONSE

Steve and his team had proven that pumps could be shut all the way down and brought all the way back up, on demand, with no damage to pumps and pipelines. He could curtail his assets enough to continue to participate in DR. The question remained, though: Would it be enough? “We were worried,” Steve says, “that if we didn’t cooperate or couldn’t participate in the test or event, there would be a penalty.” That could erase any financial benefit.

Fortunately for Steve, he had Leigh Anne Ratliff, CPower Account Executive, working with him. Leigh Anne has been with DMME since the inception of the joint DR program, and with Lake Gaston since they enrolled in the program in 2010. (She also works extensively with the City of Virginia Beach.) No one is as familiar with the DR program and Lake Gaston’s participation than Leigh Anne.

Leigh Anne told Steve that, because Lake Gaston (and the City of Virginia Beach) participate through DMME’s demand response program, there would be no consequences for not participating in a test or event. “The great thing about the DMME contract with CPower,” Leigh Anne explains, is that you really cannot be penalized. You’ll never owe anything. The worst that can happen is you’ll earn zero dollars for that test or event.”

THE RESULT: $400,000+ AND COUNTING

With penalties off the table and a successful pump shutdown protocol established, Steve continued Lake Gaston’s enrollment in the DMME DR program. He has yet to see zero dollars earned.

“We’re committed to saving money and being good stewards of public resources,” Steve says. “CPower is very supportive and encouraging for us to participate, to meet our commitments. When I first stepped into this position and informed my supervisors about the program, we all thought it was just too good to be true. But it has really worked out, and we are happy to continue participation.”

| Lake Gaston Water Supply Pipeline—Demand Response Earnings | ||

| Delivery year | kWs submitted | Earnings in $ |

| 2010/11 | 1843 | $ 99,676.00 |

| 2011/12 | 1557 | $ 53,311.00 |

| 2012/13 | 1759 | $ 30,685.00 |

| 2013/14 | 620 | $ 10,670.00 |

| 2014/15 | 1548 | $ 27,137.00 |

| 2015/16 | 1661 | $ 61,267.00 |

| 2016/17 | 1337 | $ 24,353.75 |

| 2017/18 | 1340 | $ 44,085.73 |

| 2018/19 | 1258 | $ 58,536.69 |

| Totals to date | 12,923 | $ 409,722.17 |

Case Study: City of Virginia Beach

Virginia Beach, Virginia – Energy Manager’s determined pursuit of energy efficiency savings earned the city tens of thousands of dollars in rebates in just a few short years. (Download this case study as a PDF)

THE CUSTOMER: THE CITY OF VIRGINIA BEACH

Located where the Chesapeake Bay meets the Atlantic Ocean, the City of Virginia Beach is anything but a sleepy resort town. It is the most populous city in the Commonwealth of Virginia, and boasts an economy comprising tourism, national and international corporate headquarters, advanced manufacturing, military bases, and agribusiness.

Besides the beach (the longest pleasure beach in the world, according to the Guinness Book of Records), visitors are drawn year-round to Virginia Beach’s many renowned attractions, including:

- The Virginia Beach Convention Center the nation’s first convention center to earn LEED® Gold certification as an existing building from the U.S. Green Building Council;

- The Virginia Aquarium & Marine Science Center, which attracts 650,000 visitors a year and hosts more than 10,000 fish, mammals, birds, and reptiles representing more than 300 species from around the world; and

- The Virginia Beach Boardwalk, three miles of oceanfront access, bike paths, live entertainment, restaurants, shops, and a 12-ton bronze statue of King Neptune.

Keeping the Convention Center, the Aquarium, and 350+ city buildings running in top shape uses a great deal of energy. That means, Virginia Beach is a city that understands the value of world-class demand-side energy management in municipal operations.

THE CHALLENGE: PERMANENT ENERGY (AND COST) REDUCTION

Virginia Beach’s city government serves its citizens and visitors from more than 350 facilities citywide. By 2010, constant increases in energy costs incurred at these facilities had risen to $20 million a year, a total plagued with “lost” buildings and meter reading errors in the hundreds of thousands of dollars.

To address this and other issues, including utility billing, Virginia Beach created the position of Energy Manager and hired Lori Herrick, MBA, LEED Accredited Professional, to lead its energy initiatives and manage municipal energy expenditures. With $5 million from the city, an unexpected $4 million windfall from the U.S. Dept. of Energy, and a mandate to conquer the city’s energy challenges—Ms. Herrick went to work.

THE CPOWERED STRATEGY: FINDING READY KILOWATTS

Energy efficiency (EE) projects result in permanent energy reductions, which the city recognizes as arguably the cheapest, most abundant, and most underutilized resource available to local government. With this in mind, Ms. Herrick sought to find out more about an energy program being offered through DMME, the state’s Division of Mines, Minerals and Energy. The program in question promoted energy performance contracts (EPC) to significantly reduce energy costs through energy efficiency measures that meet a guaranteed level of energy savings.

Ms. Herrick began the process of enrolling city facilities in DMME’s EPC programs, but was soon faced with the complex challenges of identifying what facilities, and how many kilowatts, to enroll. Fortunately, she received another windfall. She was introduced to CPower’s champion of Virginia demand-side energy management, Leigh Anne Ratliff.

Ms. Ratliff has worked with DMME since 2007 to offer integrated demand response services on a performance basis with no set up costs to the state. Demand response programs pay organizations such as government agencies for curtailing, or reducing, their electricity usage during times of high demand. Government entities who participate in demand response both save costs on reduced electricity use and earn revenue for their trouble.

As Ms. Herrick soon found out, CPower has an additional strength: the ability to provide complete measurement & verification (M&V) services for energy efficiency projects, necessary to receive utility rebates and credits. More importantly, CPower has unmatched experience in finding additional kilowatts (kWs) all too easily overlooked in already completed energy efficiency projects—and successfully submitting those kWs for even greater returns on the city’s investments.

CPOWERED SOLUTION: FOLLOW THE DATA (AND FIND THE MONEY)

Because the permanent energy reductions resulting from energy efficiency projects can pay dividends for up to four years after completion, Ms. Herrick and Ms. Ratliff set about the task of unearthing four years’ worth of city files to find buried EE gold – kilowatts that others missed. Looking back, Ms. Herrick says, “We were determined… it was kind of a no-brainer, to go through the files of projects we’ve done and submit the information. We were analyzing these projects to make sure the payback was there… They gave us a lot of data that Leigh Anne could use to calculate our benefit to the grid and then give us a check for it.”

From the outset, Ms. Herrick considered no project too big to tackle, working to help the Virginia Beach Convention Center earn its LEED® Gold certification (see below). She also considered no project too small to enroll, at one point submitting a 7kW project. As Ms. Ratliff explains, “If she had it, she sent it. One building got a credit for $52 in 2017. We’re learning on the cost-benefit element of this, but Lori is always looking further, to get every bit out of it that she can. In that way, she’s revolutionized what people put into energy efficiency.”

SPOTLIGHT: VIRGINIA BEACH CONVENTION CENTER

The Virginia Beach Convention Center (VBCC) is the crown jewel among the city’s facilities. It was the first convention center in the state to receive certification from Virginia Green, the Commonwealth’s voluntary campaign to promote environmentally friendly practices in Virginia’s tourism and hospitality industries. As noted above, it is also the nation’s first convention center to earn LEED® Gold certification as an existing building from the U.S. Green Building Council. These certifications are increasingly important in the competitive convention planning industry, where the VBCC competes nationally. Customer awareness of, and insistence on, “sustainable destinations” plays a greater and greater role in siting conventions.

The VBCC is also a shining example of how state-ofthe-art EE projects can enhance a city’s energy budget as well as its national reputation. Nearly all lighting in the convention center is LED lighting, and the HVAC is controlled through a state-of-the-art Direct Digital Control (DDC) system that incorporates an automated demand response program to control spikes in peak electricity demand. The automation limits any impact to convention-goers and still saves energy dollars.

“Together, we developed a process to systematically go through the building to reduce demand with the least impact on customer events.” – Leigh Anne Ratliff

It’s also a shining example of how the city and CPower Engineering worked together to successfully address one of the biggest challenges facing active convention centers: controlling peak demand electricity and total kilowatt usage. Event load-ins and load-outs at VBCC can be particularly problematic because the bay doors open directly from the loading dock into conditioned exhibit space.

“The Convention Center was a very cool energy project, because people in that space change every day,” Ms. Ratliff explains. “Bay doors are open for hours at a time, a lot of bodies and boxes moving in and out. The open bay doors are a significant source of heating and cooling loss. So how do we control that without disrupting loadins and other convention-goers already onsite?”

The first step was to analyze the status of the bay doors during times of peak demand. The Center’s zoned DDC system, which controls the Center’s HVAC, was programmed to prevent the air conditioning from running in the exhibit halls if the bay doors were open. In addition, the DDC system receives power pulses from the electricity switch gears throughout the day. In the next phase, an automated demand response program was integrated into the DDC system. When the system reads that the Center’s demand is getting ready to peak, it automatically implements one of three phases. Phase 1 changes back-of-house temperatures by one degree. If demand continues to peak, it implements Phase 2, which changes back-of-house temperatures by two degrees, all the way to three degrees at Phase 3. This automated program reduces the demand on VBCC’s chillers, which in turn reduces peak electricity demand.

“Our CPower engineers worked with VBCC’s staff to understand how the bay doors and events taking place in the building impact peak demand and usage,” Ms. Ratliff says. “Together, we developed a process to systematically go through the building to reduce demand with the least impact on customer events.”

With its DDC system program finalized and firmly in place, the Convention Center was able to ease demand on the grid, with near-zero disruption to its customers’ activities. In fact, the Center saved an astonishing 15 percent off their peak during its first year. And since the price of electricity peaks along with demand, this translated into significant cost savings that they otherwise would not have been able to attain.

THE RESULTS: $87,000 AND COUNTING

CPower is instrumental in helping the City of Virginia Beach navigate the complexities of PJM energy efficiency credits and paybacks. CPower submitted the uncovered EE data to PJM and earned the city both savings and revenue. For the delivery years 2017 through 2022, earnings from PJM for the city will reach just over $87,000 (see chart), with the VBCC earning $40,000 alone. And the city’s just getting started. “We just got another big round of funding,” Ms. Herrick says, “so Leigh Anne’s going to be hearing a lot from us.”

LOOKING AHEAD: DEMAND RESPONSE

In November, 2017, the Commonwealth of Virginia retained CPower through 2020 to continue to offer integrated demand response (DR) services to state agencies and departments through DMME. Ms. Herrick worked with Ms. Ratliff to identify five city sites they believe could be the most eligible for DR: Judicial and correctional facilities, the Convention Center, the Aquarium, and the central plant. The Convention Center currently participates in CPower’s DR program and earns revenue. The remaining facilities are undergoing audits to better understand their suitability. “DR involves curtailment, and we have to be careful when and how we curtail,” Ms. Herrick says. “That’s especially true of the aquarium. I want to earn revenue for the city, but we also don’t want to be responsible for a fish fry.” There’s no doubt, though, that Ms. Herrick will find a way to make it work. Above all else, she and the city are determined.

CPower will support their energy goals at every turn, with an energy strategy custom-made to meet their unique requirements.

SAVINGS AND EARNINGS: CITY OF VIRGINIA BEACH/VIRGINIA BEACH CONVENTION CENTER

Projects include lighting and green building. Sites include Aquarium, Boardwalk, Convention Center, library, maintenance garages, recreation centers, fire stations, police stations, EMS administrative and training center, and arts center.

City of Virginia Beach |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| 2017/2018 | 14 | 185.67 | $14,820.89 |

| 2018/2019 | 13 | 173.24 | $17,869.86 |

| 2019/2020 | 11 | 170.24 | $9,283.28 |

| 2020/2021 | 7 | 87.17 | $2,434.65 |

| 2021/2022 | 2 | 38.36 | $1,865.51 |

| Total | 654.68 | $46,274.19 | |

Virginia Beach Convention Center |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| 2017/2018 | 2 | 172.52 | $13,781.49 |

| 2018/2019 | 2 | 172.52 | $16,374.31 |

| 2019/2020 | 2 | 172.52 | $9,497.01 |

| 2020/2021 | 1 | 40.95 | $1,143.73 |

| Total | 7 | 558.51 | $40,796.54 |

Combined Totals |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| Total | 54 | 1,213.19 | $87,069.73 |

Download this case study as a PDF

Government

White Paper: Leveraging Your Generation Assets To Generate Revenue

Case Study: Desert Water Agency

2.5 MW of monthly demand response commitment gives the Desert Water Agency energy savings and additional revenue to offset costs.

The Customer: Desert Water Agency, Palm Springs, California

The Desert Water Agency (DWA) is a not for profit government agency providing water to the desert resort community of Palm Springs, in the Coachella Valley, as well as adjacent areas. Nearly all of the water that is used in the Coachella Valley comes from a groundwater basin, or aquifer estimated to contain about 30 million acre-feet of water. DWA pumps water using 29 wells spread throughout its retail area and delivers it to 23,000 water connections serving approximately 106,000 residents and businesses.

DWA embraces sustainable energy resources, including hydroelectric and solar, to power its pumps and generate energy savings. A solar field comprising 4,500 ground-mounted fixed tilt panels produces just over a megawatt of energy. The solar facility powers their Operations Center and Water Reclamation Plant and is projected to save the Agency and its ratepayers about $6 million in energy costs during its lifetime.

The Challenge: Tap the Demand Response Revenue Stream

The demand response program offered by CPower pays customers for reducing their energy usage upon same-day notification of a possible grid event. DWA understands the benefit of earning additional revenue by curtailing their power load and using that revenue to further offset energy costs. The key to DWA’s successful participation was technically implementing a curtailment program with the least possible disruption to its operations and its customers. Wells throughout the city that could participate in the program would be turned off when CPower issues a curtailment notification.

That left them with one important question: “Can we survive three to four hours of having wells shut down and still be able to refill our reservoirs to meet customer demand?”

The CPowered Strategy: One Well at a Time

Thankfully, with CPower’s help, the answer was “Yes.”

DWA chose CPower as their demand response provider to manage their participation in the demand response program. CPower provides a team of energy experts to review the Agency’s operations and energy goals. Together, DWA and CPower developed an energy management strategy that gives DWA the tools to optimize their participation in the program.

The strategy called for DWA to start with a small number of wells, to familiarize themselves with the curtailment process with minimal impact on day-to-day operations. As DWA’s staff became more comfortable with the process, more wells were added, until all eligible wells—25 of their total of 29—are now actively participating and generating revenue for the Agency.

“The CPower relationship has been outstanding… I fully trust them. The integrity is always there, they are always reliable and very knowledgeable.”

-Steve Johnson, Assistant General Manager

CPowered Solutions: Power Empowerment

Understanding the Agency’s preference for autonomy over automation, CPower empowered it with the tools to control its energy spend and demand response participation. The Agency can turn individual sites on and off at will upon notification through their supervisory control and data acquisition (SCADA) software to implement the custom-designed energy strategy developed with CPower’s experts. Perhaps best of all, the Agency can manage it all from their central Operations Center, without dispatching staff to well sites under a grid-stressing desert sun.

CPower collects utility meter data for each of DWA’s sites and supplies them with quarterly performance data. These data provide DWA with an understanding of each site’s base load value. The Agency can use these data to decide their optimum load curtailment commitment for each month of the program.

The Results: An Oasis of Cost-Saving Revenue

DWA typically nominates a changing rotation of eight wells each month into the program. The total monthly load drop amounts to about 2.5 MW. This is a significant commitment that helps relieve stress on the electric grid.

The program also provides DWA significant financial incentive for their participation. During a recent six-month period, May-October, they received $105,872.68 in payments for their participation. These incentives allowed them to further offset their energy costs, to the benefit of their customers.

Just as importantly, perhaps, DWA enjoys the total commitment of CPower’s dedicated California energy market experts. The Agency knows from experience that CPower will support their energy goals at every turn, with an energy strategy custom-made to meet their unique requirements.

Download a PDF version of this case study

Demand response contributes more than just sustainability to K-12 public school system

The Virginia Beach City Public School System is on a mission. At the heart of that mission lies a commitment to education, which you’d expect from the largest school division in southeastern Virginia. What you might not expect is how money earned from participating in demand response programs is helping fund the VBCPS’ drive toward academic excellence.

Ranked the fifth best large school division in the entire nation by GreatSchools, Virginia Beach City Public Schools (VBCPS) has earned a reputation for fostering a culture of outstanding academics.

That’s not all the school division has earned lately.

Since 2014, VBCPS has also earned over $250,000 through demand response and demand management. The increased revenue has helped pave the way for a sustainable future of energy efficiency and academic achievement.

Compass to 2020

VBCPS’ Charting the Course initiative was launched in 2015 to set the vision of school division over the next five years. The strategic framework includes four goals – high academic expectations, multiple pathways, social-emotional development, and culture of growth and excellence – and multiple strategies to guide this important work. This focus on excellence at VBCPS extends into their drive towards energy efficiency and sustainability initiatives across their entire K-12 campus system and facilities.

VBCPS understands the importance of conserving resources and protecting our environment. Among the nearly 70,000 students and approximately 15,000 employees are the often unique and innovative conservation efforts that can be found in every office and school in the division. As a testimony to this commitment, they have embraced Demand Response participation with support at all levels of the organization, from the office of the president to the facilities personnel, faculty, and students.

The Opportunity

VBCPS has been participating in the PJM Emergency Capacity DR and Energy Efficiency programs with CPower since 2013. They participate through the State Contract E194-1378 administered by the Department of Mines Minerals and Energy (DMME), which has joined forces with CPower to bring enhanced Demand Response services to Virginia.

VBCPS has 85 schools, 13 of which were registered in 2016 to participate in the Emergency DR program. The peak load of the 13 school campuses is 9.6MW of which they curtail 8MW when called upon to reduce load during times of grid emergencies. Since 2014, their efforts have brought in earnings of over $250,000, which they have used to fund additional efficiency projects to support campus-wide sustainability goals.

Consistent Success

VBCPS staff at each participating school takes ownership of their Demand Response participation and have consistently over-performed each season thanks to:

- Excellent cross-functional preparation and pre-season on-boarding with their facilities personnel and the CPower team

- End-to-end communications/notifications exercise and load drop test conducted by CPower allows the VBCPS team to identify potential issues (if any) and take actions to fix them

- Effective curtailment planning strategies to optimize load reductions with minimal impact on campus staff and students

- Complete buy-in, approvals and support from the VBCPS school division management

- VBCPS facilities team has sharp focus on setting up a detailed process for participation based on each school’s timecards and student schedules/events

- Team expectations clearly; communications plan includes command central (radio, email, telephone, text) with notifications as early as possible

Regular meetings and clear internal communications (via newsletters, posters etc.) - Team expectations clearly; communications plan includes command central (radio, email, telephone, text) with notifications as early as possible

- Regular meetings and clear internal communications (via newsletters, posters etc.)

- Every year pre-season, the VBCPS team proactively updates their Demand Response informational guide and set of procedures

- With a total of 8 staff in Central Command and 30 across the other schools; they maintain 2-3 trained staff per school, with 1 person handling a specific event at each school and the rest at back -up in the case of vacations/illness. Moreover, experienced staff members act as mentors/trainers for others that are new to the program.

Challenges and Lessons Learned

Some initial challenges included managing data from multiple utility meters as well as different building automation systems (BAS). However, the methods used above with site-specific planning allowed VBCPS to overcome the hurdles. Some sites have an Easy Button and use an automated approach while some utilize a more detailed hands-on approach.

In the end, clear communications and reliable equipment/metering are key factors for consistent performance. For instance, there was an emergency event called at the end of the season in 2013, where VBCPS delivered per their commitments even though school was fully in session. The schools also got the added benefit of earning energy payments from that event.

Forward-Thinking towards a Sustainable Future

Additionally, in 2014 the team pioneered the State of Virginia Energy Efficiency effort with lighting upgrades across the division footprint. They embraced the energy efficiency program, connecting CPower with their contractors to get the required information of qualified projects, and ultimately will earn close to $100,000 for their efforts.

Looking to the future, VBCPS has consistently added load reductions to their commitment to support grid reliability. They have added 8 more schools with an additional 2.8 MW of curtailable load to participate in the 2017 PJM performance season program, and are also exploring the PJM Economic DR program. Four new lighting upgrades from the spring of 2017 were submitted to the PJM Energy Efficiency program. The team at VBCPS are a powerful asset to demand response. By providing their operating procedures as a starting point to other participants, they have served as mentors for other schools – providing encouragement to their peers so they feel confident to take advantage of the program and optimize energy earnings and savings at other K12s across the Commonwealth.

Contact Leigh Anne Ratliff or anyone on CPower’s PJM team at www.CPowerEnergy.com/markets/pjm-interconnection-contact

Understanding kW vs kWh (and Meter Data) to Lower Your Utility Bills

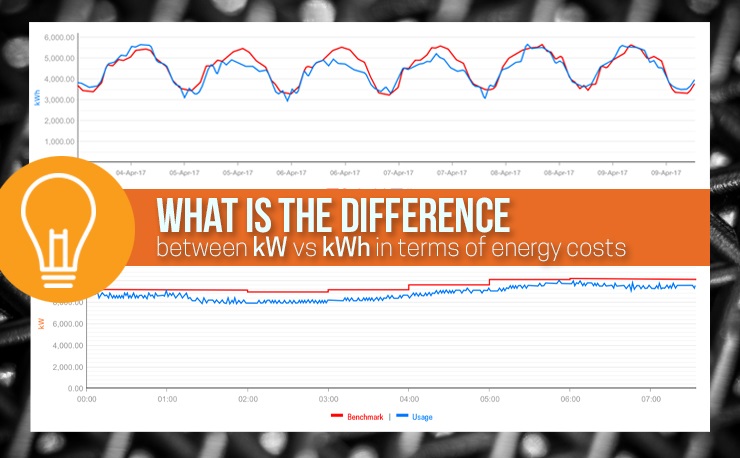

Many customers as well as my colleagues at CPower often ask me about the benefits of installing reliable metering equipment to access energy data in near real time. I typically respond with a handful of advantages (some listed below), but even before going there I find it useful to explain the full context about why these are important.

No discussion on the topic would be complete without a basic understanding of Demand (measured in kilowatts or kW) versus Consumption (measured in kilowatt hours or kWh). This is key to making the right choices when it comes to reducing energy costs, since electricity use for a commercial/industrial customer is typically billed and metered after taking at least these factors into consideration:

- Maximum kilowatt use (or kW demand) during a given period, typically in 15- or 30-minute intervals, and

- Total cumulative consumption (in kWh).

So, what’s the big deal between kW vs kWh?

An analogy using traditional light bulbs can help: Consider a single 100W bulb lit for ten hours versus ten 100W bulbs lit simultaneously for one hour. In both scenarios, the total cumulative “consumption” is 1,000 watt-hours (or 1 kWh). In the first case, however, the single light bulb will “demand” 100W or 0.1 kW from the electric supplier. Thus, the utility must have that 0.1 kW ready whenever that bulb is switched on. But note how the second scenario impacts the utility from a “demand” perspective. The electric supplier in this case must be ready to deliver 10x as much ‘capacity’ in response to the demand of the 10 light bulbs burning simultaneously!

Quite simply, here’s the difference. If these two scenarios reflected the behavior of two different customers, and if they were each billed for only their consumption, then both would get the same bill (for 1 kWh of energy used) even though the burden placed on the utility to meet each customer’s energy requirement is very different. Among other reasons, this is primarily why C&I (as opposed to residential) customers are typically metered and billed based on both their hourly “consumption” patterns and their peak “demand” for energy.

Demand-side energy management in near real time

CPower’s savvy demand response (DR) customers effectively leverage the energy they consume as a facility asset. Our diverse customer base covers mid- to large-sized electricity users in commercial, industrial, government and institutional organizations, including water/wastewater pumping and treatment facilities, colleges and universities, public agencies, office campuses, cold storage, data centers and a wide range of manufacturing facilities, to name just a few.

Many of our most active DR participants nationwide additionally leverage real-time metering for its clear advantages, including more visibility and control over load reductions as well as better overall energy management and sustainability benefits. The image above shows just two of the many views available to users via the CPower App (the graph on top shows 7-day hourly interval consumption while the one below shows demand on an intra-day 1-minute interval chart).

Key reasons to get real-time metering installed at your facility:

- You can identify unusual or erratic equipment behavior to help avoid catastrophic failure. This is from a recent real-world example: Our team at CPower was working with the operations team for a large commercial real estate and property management firm, and picked up on unusual/erratic daytime usage patterns at one of their facilities. A look at the major systems of the building revealed that a chiller which had been recently serviced was to blame. Further investigation revealed that during a recent service call the chiller had been severely over-charged with refrigerant. Having a near real-time window into their energy usage enabled the facilities personnel to identify the unusual usage pattern, and proactively remedy a potential chiller issue that could have resulted in thousands of dollars in repair costs and possibly escalated their demand charges had it gone unnoticed.

- Similarly, you may discover unusual, wasteful patterns or aberrations in overall facility energy usage as well as specific areas (e.g., an BAS reset inadvertently switches on all lights in an unoccupied underground parking garage at 2 AM).

- Simplify on-site event planning (e.g., for K-12 schools or colleges) and/or production line scheduling (for manufacturing) with day-ahead pricing and forecasting at your fingertips.

- Quickly and accurately substantiate the impact of your energy efficiency initiatives and sustainability programs (and share results with your team and management).

- Avoid setting a new annual or monthly consumption peak, enabling you to manage demand charges for next year. Click to see more on Peak Demand Management in New England and Texas, for example.

- Immediately evaluate the efficacy of (and fine tune as needed) new load curtailment strategies.

- Further leverage your building automation systems and curtailment planning while minimizing impact on occupants (students, staff, employees, tenants, etc.).

- Facilitate optimized participation in multiple DR programs, including Emergency Capacity, Economic DR, Ancillary Services, and more.

- In addition to monitoring real-time utility load, several customers (i.e. a manufacturer of water valves and a supplier of military components) also view sub-meter data in the CPower App to provide them with a more granular, process-level picture of the energy usage in their facility.

The Bottom line

Real-time metering ultimately increases your DR earnings and savings to fund additional efficiency initiatives, while complementing your facility’s energy conservation and sustainability efforts. There are no out-of-pocket costs, since fees to install hardware, support software provisioning and enable data measurement & verification (M&V) are typically covered by DR program earnings.

By giving you near real-time visibility and analytics of your energy consumption, enhanced metering techniques provide more earnings and savings via greater control over your DR participation and greater awareness of electricity usage patterns (remember kW vs kWh!)